Introducing the most technically advanced pipework sets in the world

SERPENT SYSTEMS

SERPENT SYSTEMS

For years motorcycle exhaust manufacturers have dreamed of creating the most perfectly sculptured headers and system pipework to maximize the gas dynamics and maintain the gas inertia to improve cylinder filling - creating the absolute maximum power available.

Now Micron has made that dream a reality

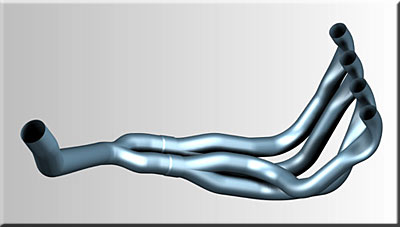

A combination of world renowned Ricardo Wave design software and our state of the art manufacturing facility has allowed us to refine the pressure wave action and gas particle flow. Beautifully sculptured and patented Micron Serpent headers with our exclusive "Serpent" headpipe shape reduce the energy losses and improve scavenge wave action. Result? Accelerated gas flow dynamics helping you to get the maximum horsepower available from your machine.

Need a simpler version? Take the extremely high speed gas particle flow of your exhaust as it leaves the exhaust port, and picture it entering the first bend in the exhaust header. By centrifugal force, all the gas is "pushed" to outside of the bend in the pipe, causing a vacuum, or "reversion", on the inside bend of the pipe in this same location. Much the same as watching a fast flowing river entering a bend, you can see the water working its way back "up river" at the inside of the bend, which is what is called negative flow. Through the use of the most sophisticated software and engineering in the world, we create the "Serpent" header design that virtually eliminates this negative flow, while still maintaining the pressure wave and velocity at almost a perfect level. The end result is a stronger pressure wave for scavenging and minimal loss of exhaust gas velocity, both of which translate to MORE HORSEPOWER!

How are these pipes made? It should be obvious that this is a technology which is far beyond the average world of bending pipe so common in the industry today, and that is where Hydratech steps inů

Hydra was a figure in Greek mythology with serpents gyrating out of her head - and so it is that Micron introduces Hydratech formed exhaust pipework. Created under an incredible 75,000 psi of water pressure and sculptured to deliver quite simply the fastest, smoothest and maximum power enhancing pipework sets ever seen - Hydratech pipes will very quickly become the mark of racers who will only accept the very best for their bike

Hydra was a figure in Greek mythology with serpents gyrating out of her head - and so it is that Micron introduces Hydratech formed exhaust pipework. Created under an incredible 75,000 psi of water pressure and sculptured to deliver quite simply the fastest, smoothest and maximum power enhancing pipework sets ever seen - Hydratech pipes will very quickly become the mark of racers who will only accept the very best for their bike

By using water pressure to "mold" the pipes (as compared to simple bending), Micron is able to create virtually any shape, size or design our engineers can dream of. No longer are we limited by available pipe sizing, bend angles, or pipe placement when creating a header system. Serpent headers can use any and all possible avenues to maximize horsepower, including designs and shapes never

before seen in the regular world of exhaust systems.

By using water pressure to "mold" the pipes (as compared to simple bending), Micron is able to create virtually any shape, size or design our engineers can dream of. No longer are we limited by available pipe sizing, bend angles, or pipe placement when creating a header system. Serpent headers can use any and all possible avenues to maximize horsepower, including designs and shapes never

before seen in the regular world of exhaust systems.

Add to this the benefit that since the pipes are molded with the correct sizes and tapers wherever we choose built right into the pipe, we require almost no welds and are therefore able to minimize the material being used for the pipes, making for some of the lightest and yet most durable headers ever produced.

Add to this the benefit that since the pipes are molded with the correct sizes and tapers wherever we choose built right into the pipe, we require almost no welds and are therefore able to minimize the material being used for the pipes, making for some of the lightest and yet most durable headers ever produced.

Competitors who have to "weld" pieces and parts into place need thick material to help the welds hold, and this increases the weight of their systems.

Micron Serpent headers not only are the highest performance available, they also are some of the lightest and most beautifully engineered products ever seen in the manufacturing world.

Competitors who have to "weld" pieces and parts into place need thick material to help the welds hold, and this increases the weight of their systems.

Micron Serpent headers not only are the highest performance available, they also are some of the lightest and most beautifully engineered products ever seen in the manufacturing world.

The Ultimate pipework sets in the world today

Up to 40% lighter than conventional pipework

Up to 8% more gas flow, capacity & speed

Fewer unsightly and power robbing welds & joints

Sleek , fast & durable sculptured look

A world first from a world class manufacturer

The exclusive and patented Micron Serpent headers are available on a very limited basis for a handful of the finest high performance machines, please contact us for updates on availability and options.

"We at the Castrol Honda British Supersport Team like to use the best products that are available to us. That is why we choose Micron. After running tests with other leading manufacturers we found the Micron systems to be the BEST. Not only do the pipes make the best of the CBR600 power characteristics but the support and ongoing development from Micron, is one that you can always rely on."

Roger Harvey - Honda UK Race Coordinator

"The Micron Systems transformed our season. We were struggling with fuel management but when we fitted the Micron system we were not only able to cure our problems but also gain a significant performance increase. We finished the year 1st Production Superbike and also won the Superbike manufacturers trophy. We wouldn't use any other system on our CBR900 or CBR600. We want to win."

Brad Bennett - Team Manager Honda Australia

"Young Sanyo hotshots Chris Vermeulen and Glen Richards were helped considerably by the increased performance given by the Micron exhausts fitted to ALL Sanyo - Honda bikes. Micron proved great on performance, very reliable, no breakages, and together with excellent R&D facilities and race support means Micron continues to be our Number 1 choice."

Russell Savory - Sanyo First National Honda

"Micron proved to be the best for us on the Production Yamaha R1 giving excellent power and torque. Micron's race back up is the best in the country. Together at the 2000 Isle of Man TT we proved to be a winning combination for the second year running."

David Jefferies - 2 Time Isle of Man TT Production Winner